- Home

- Function/Function Block Reference

- Safety-Related PLCopen Function Blocks

- SF_EmergencyStop

SF_EmergencyStop

Help version 1.1 / Issue date: 2018.03

The following description is valid for the function block SF_EmergencyStop_V2_0z, Version 2.0z (where z = 0 to 9).

| Short Description | The

safety-related

SF_EmergencyStop function block monitors the switching states of an emergency-stop control device. When the connected emergency-stop device is activated, the enable signal at output S_EStopOut becomes SAFEFALSE. S_StartReset can be used to specify a start-up inhibit and S_AutoReset can be used to specify a restart inhibit. |

|||||||||||||||||||||||||||

| Block Icon |  |

|||||||||||||||||||||||||||

| Inputs |  Activate Activate

Refer to the topic "Activate" for details.  S_EStopIn S_EStopIn

Refer to the topic "S_EStopIn" for details.  S_StartReset S_StartReset

Refer to the topic "S_StartReset" for details.  S_AutoReset S_AutoReset

Refer to the topic "S_AutoReset" for details.  Reset Reset

Resetting the function block by means of a positive signal edge at the Reset input can cause the S_EStopOut output to switch to SAFETRUE immediately (depending on the status of the other inputs).

Refer to the topic "Reset" for details. |

|||||||||||||||||||||||||||

| Outputs |  Ready Ready

Refer to the topic "Ready" for details.  S_EStopOut S_EStopOut

Refer to the topic "S_EStopOut" for details.  SafetyDemand SafetyDemand

Refer to the topic "SafetyDemand" for details.  ResetRequest ResetRequest

Refer to the topic "ResetRequest" for details.  Error Error

Refer to the topic "Error" for details.  DiagCode DiagCode

Refer to the topic "DiagCode" for details. |

|||||||||||||||||||||||||||

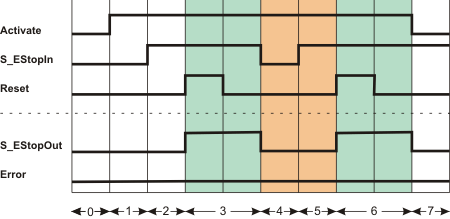

| Detailed information |  Signal sequence diagram Signal sequence diagram

This diagram relates to a typical emergency-stop function with an active start-up inhibit and an active restart inhibit:

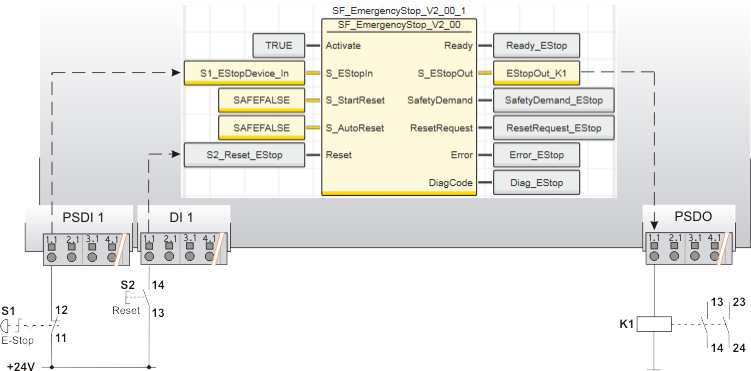

Application example Application example

This example illustrates a single-channel connection of the N/C contact of an emergency-stop control device S1 with the safety-related SF_EmergencyStop function block. The emergency-stop control device is connected to input terminal 1.1 of the safety-related input device PSDI with an ID of 1. In this example the following applies:

The function block is perpetually activated by the TRUE constant at the Activate input. S_StartReset = SAFEFALSE specifies a start-up inhibit after the Safety PLC has been started up or the function block has been activated. Furthermore, S_AutoReset = SAFEFALSE specifies a restart inhibit of the function block after the emergency-stop control device has been deactivated, i.e., once the SAFETRUE signal has returned at the S_EStopIn input. Both inhibits are only removed when there is a positive signal edge at the Reset input. To this end, the S2 reset button is connected to input 1.1 of the standard input device DI 1.

Function block instantiation Function block instantiation

The IEC 61131-3 standard defines function block instantiation. Instantiation means, a function block is defined once and can be used (instantiated) several times. This applies to all FBs (user-defined POUs as well as library FBs, such as IEC standard FBs, firmware FBs, user library FBs).

Why instantiation? The following applies:

The user-defined function block 'TLC' ("Two Level Controller") is added to the 'Functions & Function Blocks' category (COMPONENTS area). It shall be called twice in the program POU 'Container' to control the filling level and the temperature of a boiler. For both FB instances, an instance name declaration is added to the 'Variables' table of the calling program POU 'Container': TLCTemperature and TLCLevel. Thus the 'TLC' function block can be called twice in the code worksheet of the calling POU by means of these instance names. |