Safety Violation Messages and Data Integrity Errors

While editing safety-related data (SNOLD code worksheets, variables, the Safety PLC Data List, configuration of the Safety PLC runtime, safety-related device parameters, releasing safety-related IEC or CFB libraries, etc.), the respective editor performs a continuous verification of the worksheet data consistency: the data in the data storage is compared to the data shown in the editor thus preventing unintentional and unrecognized data modifications.

Sealing Data

After each editing operation, verified correct data is sealed by calculating a checksum over it and writing the checksum into an inventory file (which is in turn protected by a seal).

| Note

These automatically and continuously created seals should not be confused with the verification marks which can be set manually by the user for completed and verified safety-related code networks. |

Any detected inconsistency (i.e., possible data corruptions) results in an editor error and a safety violation notification. A data corruption may be caused by a technical error (faulty memory), a systematic error or a conscious (criminal) manipulation. Safety breaches due to wrong or non-compliant (with regard to applicable standards) device parameterization, code or variables are not considered as safety violation in this sense.

During project compilation, the data integrity of the compiler data is verified. These checks are also done by verifying the seals calculated by the safety-related editors.

Two severity levels in case of inconsistency

Two severity levels are distinguished in case of a safety violation:- Fatal errors lead to an exception error. PLCnext Engineer is then closed, without saving any modification before. The project, however, can be opened again and, depending on the data status, further editing is possible or the project is visible in read-only mode. At least, printing the project or copying data is possible.

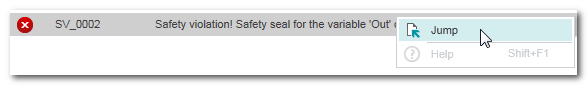

- Non-fatal errors lead to a safety violation message in the Error List (MESSAGES window, located in the Cross Function Area at the lower screen border). Each message has an error number and help information can be called by right-clicking the message.After a safety violation message has been output, you can continue editing the project. Compiling and building the project, however, is not possible, as long as the safety violation exists.You can inspect the affected error location, verify its correctness and then confirm the verification. After the confirmation, the safety-violation message is removed and the project is compilable again.

How to inspect the cause for a safety violation message and confirm the verification

- In the Error List, double-click the error message to jump to the affected editor position.

(Alternatively, select 'Jump' from the context menu.)Example: In our example, the Data List of the Safety PLC is opened and the affected variable is marked.

In our example, the Data List of the Safety PLC is opened and the affected variable is marked. - Inspect the affected data in the corresponding editor and verify its correctness.

- If the data is not correct, try to correct it. In case of a data corruption and if no correction is possible, the project is damaged and cannot be used any longer. The safety violation will persist and the project cannot be built.You can try to copy the data into a newly created project.

- If the data is correct, you can eliminate the safety violation message by right-clicking the affected editor position and selecting the 'Confirm Verification' command from the context menu.The safety violation message is deleted and the project can be built again.

You can continue the project development.