Individual Activation of Safety Equipment

Individual activation/deactivation of safety equipment refers to the possibility of manually connecting and disconnecting different, mutually independent safety-related functions. This equipment cannot be operated when disconnected.

|

WARNUNG

|

Unintended start-up

|

Single-channel application

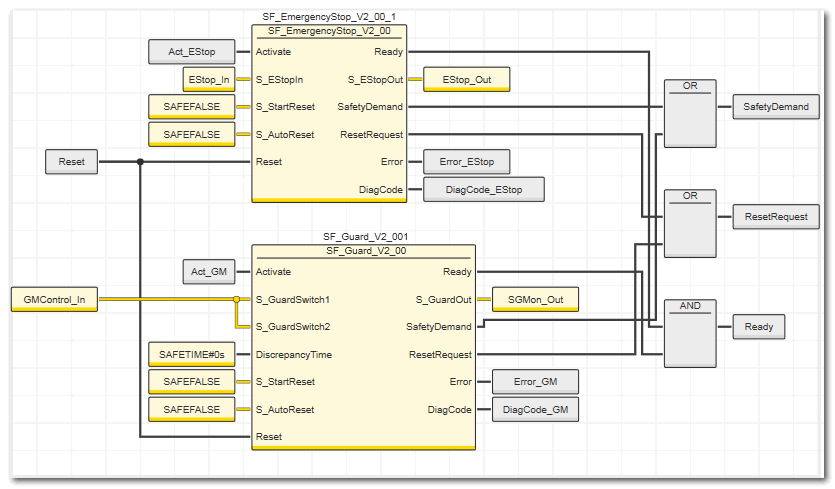

The graphic below shows a code example for this type of individual deactivation in a single-channel layout.

In this example, different items of safety equipment, which are evaluated by different safety-related function blocks, act on different safety-related outputs of the Sicherheitssteuerung: For the function block SF_EmergencyStop on output S_EStopOut (global I/O variable EStop_Out) and for SF_GuardMonitoring on output S_GuardMonitoring (global I/O variable SGMon_Out). These outputs control different safety-related functions.

The safety-related function blocks are activated (with the Activate input) via different signals or Sicherheitssteuerung inputs.

When a safety-related function block is deactivated (with the Activate input), the relevant output/safety zone is disconnected.

Two-channel application

If the risk analysis shows that the safety equipment needs to be implemented on a two-channel basis, the example shown above must be implemented with two-channel input/output signals.