Replacing Devices in the PLANT

This topic contains the following sections:

You can replace a single device (controller, device, module, submodule etc.) that is contained in the PLANT by another device type. This allows you, for example, to replace a controller by another controller type while retaining all of the settings, the network configuration (network devices), task configuration, etc. as far as possible.

When replacing a device, PLCnext Engineer tries to retain as much data as possible (settings, topology connections, variable connections, data lists connections, etc.) and use it with the new device. Which data can be retained for a replacement device depends on whether the data remains valid and is still suitable with the new device. When you replace, for example, a controller by a newer version of the same controller type, the maximum amount of data is retained.

On replacement of a device, observe the following:

- If safety-related devices are affected by the replacement, you must observe the described safety requirements.

- When replacing safety-related devices by an updated version, take the notes below into consideration.

- Devices can only be replaced by devices of the same type (controller by controller, Profinet device by Profinet device, etc.).

- Devices cannot be replaced by devices of the same type and same version (i.e., which have the same type name as indicated in the COMPONENTS area).

- A non-safety-related controller can be replaced by a safety-related controller. Replacing a safety-related controller by a non-safety-related controller is not possible.

- A controller can only be replaced by another controller when no devices are lost. If, for example, the controller to be replaced contains Axioline F devices and the replacement controller does not support Axioline F, replacement is not possible. A corresponding message is generated in the Project Log in the MESSAGES window. To replace the controller, you first have to delete the unsupported devices in the PLANT configuration and then repeat the replacement operation.

- PLCnext Engineer checks whether the replacement of a device in the PLANT is allowed. For instance, when you try to replace a device by an invalid device via drag and drop from the COMPONENTS area (see description below), the "not allowed" cursor indicates the inadmissible operation.

- Information on the replacement procedure is recorded in the Project Log in the MESSAGES window. Discarded replacement operations, such as discarded connections between variables and process data items in the device's data list or discarded tasks and events settings are indicated by a corresponding message.

The following table describes, on which devices in the PLANT the Replace function can be applied and which data is retained if valid and suitable for the replacement device.

| Device | Transferred data |

| Controller |

- Controller dataThe manually entered settings in the 'Settings' editor of the controller (such as 'Function' and 'Location'), or the station name and hostname are retained. Also the hardware extensions and Ethernet settings are retained. Device-specific settings (read-only parameters) such as the product name, version, etc. are not retained and have to be defined newly after the replacement.

- Controller Data ListRole connections (assignments of global variables to process data items and HMI tags) in the Data List of the controller are retained if they are still valid after the replacement.Refer to the hazard message in the section "Safety requirements when replacing the Safety PLC...".

- Task configuration ('PLCnext' node content)The following data in the editors of the 'PLCnext' node are retained:

- ESM configurations with valid tasks and program instances in the 'Tasks and Events' editor.

The ESM configurations are only retained if the controller architecture is the same (PLCnext Technology/conventional). Otherwise, the current ESM configuration is discarded and replaced by the initial ESM configuration of the replacement controller.

- GDS Port List with 'IN Port' and 'OUT Port' assignments.

- Subsystem with configured network devicesAll network devices (Profinet devices/modules/submodules, Axioline F modules, etc.) with the relating configuration parameters and variable assignments are retained.

- HMI data ('HMI Webserver' node content)The following HMI data in the editors of the 'HMI Webserver' node are retained:

- HMI Webserver settings such as the 'Session Timeout', 'Data Poll Interval', 'Security' setting, and port settings.

- HMI tags with assigned global variables in the 'Data List' editor.

- HMI pages, HMI support pages and HMI navigation.

- HMI symbols which are connected to an HMI tag.

|

| Profinet devices, modules, and submodules |

- The 'Function' and 'Location' descriptions in the 'Settings' editor are retained.

- All device/module/submodule parameters which have identical descriptions (names) in the device-specific description files (FDCML) files are retained.

- All process data items in the relating Data List with equal 'I/O', 'Type', and 'Offset' values and the 'Function' and 'Comment' settings for the variables are retained.Refer to the hazard message in the section "Safety requirements when replacing the Safety PLC...".

- Subsystem of the device/module.All modules/submodules of a device/module with the relating configuration parameters and Data List settings are retained.

|

| Axioline F modules |

- The 'Function' and 'Location' descriptions in the device's 'Settings' editor are retained.

- The consecutive numbers of the Axioline F devices in the 'Device List' editor under the 'Axioline F' node are retained.

- All device parameters which have identical descriptions (names) in the device-specific description files (FDCML) files are retained.

- All assignments of process data items to variables and HMI tags in the Data List of the device are retained.

|

| Inline modules |

- The 'Function' and 'Location' descriptions in the 'Settings' editor of the device are retained.

- All device parameters which have identical descriptions (names) in the device-specific description files (FDCML) files are retained.

- All assignments of process data items to variables and HMI tags in the Data List of the device are retained.

|

Notes on the replacement of safety devices by an updated version

A device type in PLCnext Engineer may be updated by a newer version by adding, for example, a new library (version) or by updating the PLCnext Engineer software, or by importing a new version of the corresponding device description (FDCML) file.

When replacing a safety-related device in the PLANT by an updated version as described below, PLCnext Engineer tries to adapt the parameter model of the device instance to the new device description.

Whenever possible, the parameter values set before the update are adopted for the device instance so that no editing of the parameterization is necessary after the update.

However, if it is not possible to take over the settings due to newly added or changed parameters, the following scenarios are possible:

- If a parameter has been added with an ID that was not used before, this parameter will be initialized with its default value. Set the parameter to the required value.

- If a parameter has been deleted, it is removed from the parameterization. No actions are required.

- If a parameter has been modified but its definition differs from the previous device version, the behavior depends on type-specific properties. The following is possible:

- Modifications of the parameter name, description or unit are taken over. In this case, no action is required.

- Modified parameters are initialized with their default values and they are shown read-only in the parameterization editor. Set the parameters accordingly and confirm them.

- An error occurs. Either the device replacement is rejected, or the replacement is done but an error message is reported and an entry into the SafetyLog (and in the migration report - see below) is made. In this case, the safety-related parameter editor can only be opened after confirming the message. Inspect the affected parameter and take the measures required.If an invisible safety-related parameter causes the error, i.e., if you have no possibility to correct the parameter value, a safety violation is reported. Inspect the SafetyLog which parameter is affected.

In each case, PLCnext Engineer logs each modification in the parameterization which result from the update of the device instance in a migration report. The log file (*.log) is written into the log directory of PLCnext Engineer:

%PUBLIC_DOCUMENTS%\PLCnext Engineer\Logs

Its file name starts with SafetyDeviceReplace supplemented by date and time of creation.

Safety requirements when replacing the Safety PLC or safety input/output modules

When replacing a controller that includes a Safety PLC or other safety-related devices, the I/O mapping of safety-related global variables may change. This may be due to the fact that addresses change or process data items of the Safety PLC are no longer available after the replacement. If the replacement is done after the I/O check has already been performed, such I/O changes could go undetected.

To help detect I/O modifications after a Safety PLC/safety device replacement, note down the Global Variables checksum before the replacement and manually compare it with the calculated value after the replacement. The Global Variables checksum is displayed in the 'Safety Information' editor. Double-click the 'Project' node in the PLANT to open this editor.

Non-conformance to safety requirements

- Make sure that the Global Variables checksum (displayed in the 'Safety Information' editor) is identically before and after replacing the safety device.

- Correct the assignment of safety-related variables and process data items if the Global Variables checksum has been changed due to the replacement.

- Make sure that the safety-related project is not written to the Safety PLC until the correct safety-related I/O mapping has been validated.

|

After replacing safety-related input or output modules, physical addresses may be changed. You must revalidate the I/O mapping (assignment of safety-related variables to safety inputs/outputs).

Unintended machine operation

-

Inspect and correct as necessary any global I/O variable addresses related to physical, safety-related I/Os whenever you replace a safety-related device.

- Validate the physical wiring of your safety-related architecture and thoroughly test the application whenever you replace a safety-related device.

|

How to replace a device

You have several possibilities to replace a device with PLCnext Engineer:

Replacement via the device's context menu in the PLANT

Replacement via the device's context menu in the PLANT

- In the COMPONENTS area, search for the replacement device and select it.

- Press <Ctrl>+<C> or select the 'Copy' command from the device's context menu to copy the device to the clipboard.

- In the PLANT, select the device to be replaced and choose the 'Replace' command from the device's context menu. Alternatively, press <Ctrl>+<Shift>+<R>.The 'Replace' command is only executable when the replacement operation is allowed for the selected device.

The successful replacement operation is indicated in the Project Log in the MESSAGES window.

Replacement via the station editor of a Profinet device ('Module List') or Axioline F device ('Device List')

Replacement via the station editor of a Profinet device ('Module List') or Axioline F device ('Device List')

There are two possibilities to replace a device via the station editors ('Device List'/'Module List'):

- Replacement via Role Picker (see method 1 below).

- Replacement by cutting or copying an existing device to the clipboard and calling the 'Replace' command (method 2).

The following procedures are similar for the replacement of Profinet devices/modules (via the 'Device List'/'Module List' editor) and Axioline F devices (via the 'Device List' editor). In the following examples, the replacement of an Axioline F device is described. Replace other devices in the same manner.

Method 1:

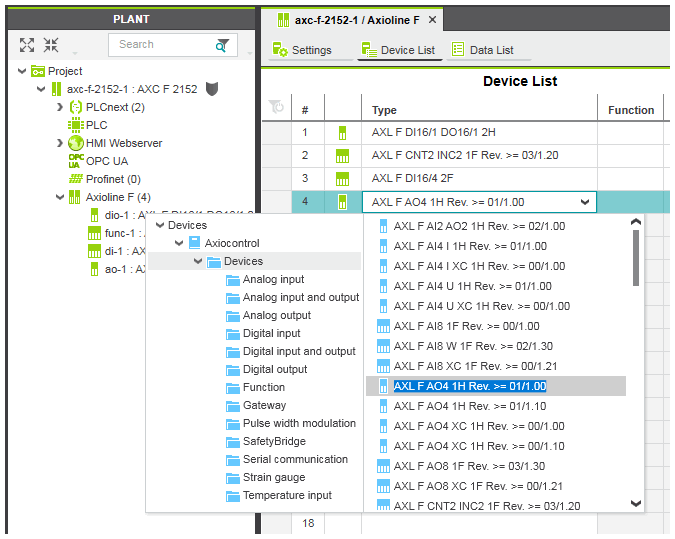

- Double-click the 'Axioline F' node in the PLANT and open the 'Device List' editor in the editors area.

- In the 'Type' field, left-click on the device you want to replace.

Alternatively, move the table cursor using the arrow keys to the desired 'Type' field and press <Enter>.The Role Picker appears for selecting devices providing only devices for selection that are allowed to be inserted at the selected position.

Example for the device selector opened for an Axioline F device:

Example for the device selector opened for an Axioline F device:

- Select the folder in the tree on the left and then the replacement device on the right by clicking it or pressing the <Enter> key. Use the following keys to navigate:

| Press the shortcut ... | ... to ... |

| <Tab>/<Shift> + <Tab> | switch between the folders on the left and the entries on the right. |

| <ArrowDown>/<ArrowUp> | move the cursor down/up. |

<Enter>

(focus on the right side) | select the currently marked entry, close the selection control and apply the entry to the table field. |

<ArrowRight>/<ArrowLeft>

(focus on the left side) | expand/collapse the currently marked folder on the left. |

The successful replacement operation is indicated in the Project Log in the MESSAGES window.

Method 2:

- Double-click the 'Axioline F' node in the PLANT and open the 'Device List' editor in the editors area.

- In the table, right-click the row with the replacement device and select 'Cut' or 'Copy' from the device's context menu. (Alternatively, press <Ctrl>+<C> to copy or <Ctrl>+<X> to cut the device).

- Left-click on the table row with the device you want to replace and select the 'Replace' command from the device's context menu.

The successful replacement operation is indicated in the Project Log in the MESSAGES window.

Replacement via Drag & Drop from the COMPONENTS area into the PLANT

Replacement via Drag & Drop from the COMPONENTS area into the PLANT

- In the COMPONENTS area, search for the replacement device.

- Left-click the device, press the <Shift> key and drag the device to the PLANT while keeping the <Shift> key pressed.

- Drop the object on the device to be replaced.

PLCnext Engineer checks whether replacement of the device is allowed. The cursor changes as shown in the following figure when it is allowed to drop the replacement device. An inadmissible operation is prevented by the system and indicated by the "not allowed" cursor:

The successful replacement operation is indicated in the Project Log in the MESSAGES window.

Replacement via the device's context menu in the PLANT

Replacement via the device's context menu in the PLANT

Replacement via Drag & Drop from the COMPONENTS area into the PLANT

Replacement via Drag & Drop from the COMPONENTS area into the PLANT