Profisafe Device Identification: F-Parameters

In a Profisafe network, the Safety PLC, which acts as F-Host, and the safety-related devices (F-Devices), are identified by means of F-addresses:- The F-Host in a Profisafe network is uniquely identified by its source address: F_Source_Address. This address is used for the communication relationships to all safety nodes (F-Devices) which are assigned to this F-Host.Consider the special case that a Safety PLC is used as both F-Host and F-Device.Set the source address of the F-Host in PLCnext Engineer as follows:

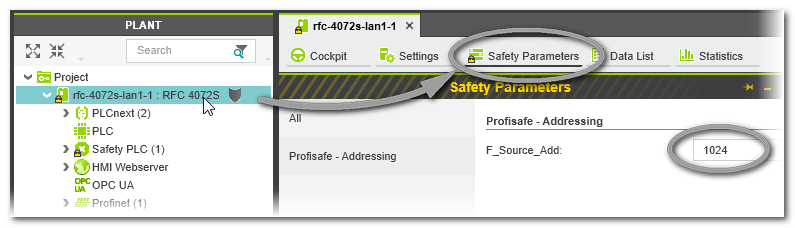

- In the PLANT, double-click the controller node and open the 'Safety Parameters' editor.

- In the 'Safety Parameters' editor enter the 'F_Source_Add'.

Value range: unique decimal value between 0 and 65535.

- Each safety-related device is identified by a destination address F_Destination_Address, or F_Dest_Add.Consider the special case that a Safety PLC is used as both F-Host and F-Device.Set the source address of each F-Device in PLCnext Engineer as follows:

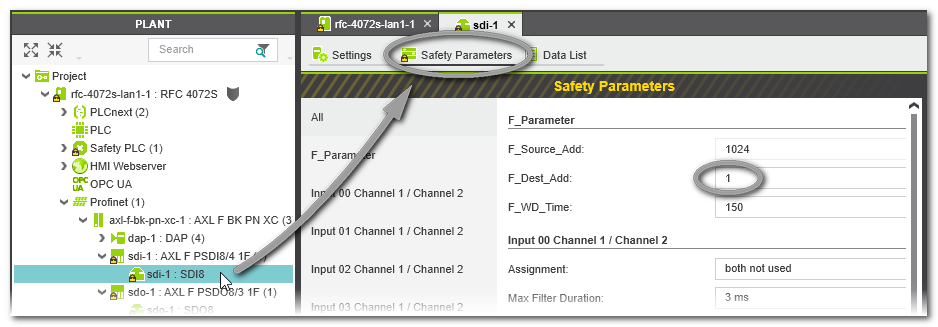

- In the PLANT, expand the safety-related Profisafe device under the 'Profinet' node and double-click the submodule node. Open the 'Safety Parameters' editor.

- In the 'Safety Parameters' editor enter the 'F_Dest_Add'.Value range: PLCnext Engineer checks the validity (value range and uniqueness) of the entered value directly while editing.

- For safety modules from Phoenix Contact, you can set Profisafe decimal destination addresses from 1 to 999, maximum.

- For safety modules from other manufacturers, destination addresses from 1 to 65534 are supported.

In applications with several F-Hosts, each F-Host and its assigned F-Devices are considered as island.

The maximum number of connectable F-Devices per F-Host depends on the host type.

The RFC 4072S controller, for example, supports a maximum of 300 F-Devices.

| Note

Observe the limitations described in the respective user manual, for example, regarding the maximum length of safety-related input or output messages. |

| Note

F-Parameters and I-Parameters - Term definition The address parameters (source address of the F-Host and F-Device destination addresses) are collectively referred to as F-Parameters. Within a Profisafe network, these addresses must be unique. The term I-Parameters refers to the data record consisting of the safety logic and the safety-related channel parameters (input/output parameters). This means, I-Parameters specify the configured safety function and the channel parameters of the devices concerned. In the 'Safety Parameters' editor of the respective device in PLCnext Engineer, they are listed in channel-related parameter categories. |

Safety PLC acts as F-Host and F-Device

Consider the following scenario:

| Note

This scenario is only possible for particular controller types. |

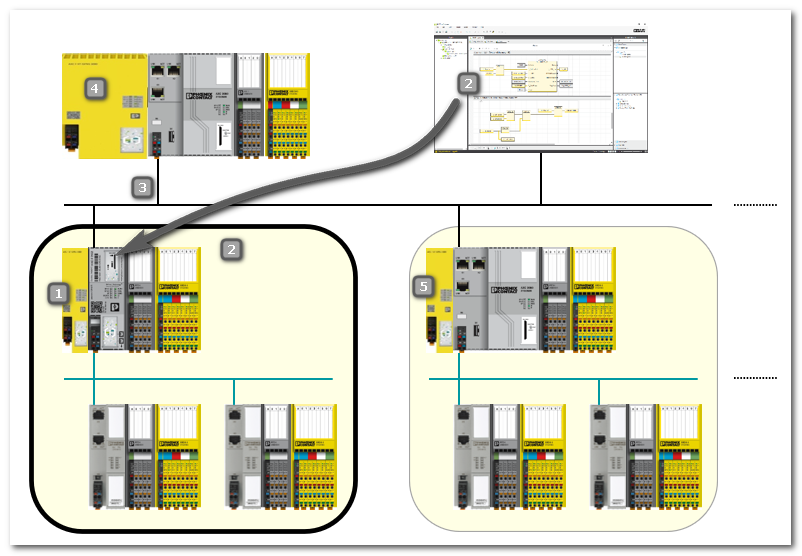

- The Safety PLC (no. (1) in the figure) acts as F-Host of the Profisafe network you are currently developing in your PLCnext Engineer solution (2). Therefore, it needs an F_Source_Address for its own Profisafe network.

- At the same time, the Safety PLC (1) in your solution (2) acts as F-Device in a superimposed Profisafe network (3). This superimposed Profisafe network has its own F-Host (4) and possibly further F-Devices (5) besides your Safety PLC (in further subordinate networks). In this case, your Safety PLC also needs an F_Destination_Address as Profisafe client of the superimposed network.

Only in this scenario, the following applies:

- The Safety PLC in your solution needs both an F_Source_Address and an F_Destination_Address.

Both addresses must be defined in the 'Safety Parameters' editor as described above. - The F_Destination_Address of the Safety PLC may be the same as the F_Destination_Address of another F-Device used in your solution. This is allowed as the addresses belong to different Profisafe networks.

- The F_Destination_Address of the Safety PLC may be the same as its F_Source_Address. This is allowed as the addresses belong to different Profisafe networks.

- The safety application you are developing in your solution relates to the current Profisafe network in which the Safety PLC is the F-Host.

- The communication between the superimposed Profisafe network and the Safety PLC (as F-Device) is done using special system variables. Currently, 16 SAFEBYTE variables can be exchanged between the upstream F-Host and the Safety PLC in your solution:These safety-related system variables are available in the Data List of the 'Safety PLC'. Here, they can be assigned to global variables of the standard controller in order to read them in the standard application.

- FDEV_IN0 to FDEV_IN7 can be written by the F-Host of the superimposed network and read by the Safety PLC in your solution.

- FDEV_OUT0 to FDEV_OUT7 can be written by your Safety PLC and read by the F-Host of the superimposed network.

Example:

Example: