Profisafe Communication/F-Device State Diagnostics

In a safety-related application, the safety-related communication and the operational state of safety-related devices should be monitored. This enables the Safety PLC to determine the state of the functional safety system.

For that purpose, PLCnext Technology controllers may provide system variables which reportIn PLCnext Engineer, such diagnostic system variables should be evaluated in the application program, e.g., by programming an edge detection which reacts on the toggling of the Boolean values.

To inform the standard application about the condition of the functional safety application, the system variables can be assigned to exchange variables of the standard controller. Refer to the topic "Exchanging Data between Controller and Safety PLC" for details.

In case of a safety-related device/communication error, the machine must enter the defined safe state.

|

WARNING

|

Unintended machine operation

|

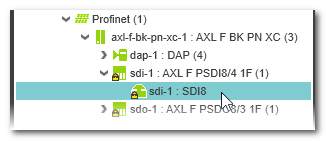

- F-Device-related system variables: available for each configured Profisafe device. Such device-related system variables contain the F-address (XXXXX) of the affected device in the variable name: F_ADDR_XXXX_*.

- Global system variables for F-Devices which summarize all configured F-Devices. A global system variable is set to TRUE, if the respective condition applies to at least one configured F-Device.

The creation of these system variables can be enabled/disabled in PLCnext Engineer as described below.

| Note

Besides the diagnostic system variables, also variables for the device management may be available. Refer to the respective controller user manual for details. |

| Note

F-Parameters and I-Parameters - Term definition The address parameters (source address of the F-Host and F-Device destination addresses) are collectively referred to as F-Parameters. Within a Profisafe network, these addresses must be unique. The term I-Parameters refers to the data record consisting of the safety logic and the safety-related channel parameters (input/output parameters). This means, I-Parameters specify the configured safety function and the channel parameters of the devices concerned. In the 'Safety Parameters' editor of the respective device in PLCnext Engineer, they are listed in channel-related parameter categories. |

Monitoring the Profisafe Communication

With regard to the monitoring of the Profisafe communication, two different error types are distinguished and different diagnostic system variables are relevant:

| Error type | Relevant diagnostic system variable |

|---|---|

| Checksum error |

|

| Watchdog exceeded |

|

| Failed loopback check | Communication error reported by an F-Host and detected when performing a loopback

check. The system variable is available F-Device-related (F_ADDR_XXXXX_LOOPBACK) and globally LOOPBACK_GLOBAL. |

| Further Info

For a detailed description of all available Profisafe system variables, refer to the respective controller user manual. For the RFC 4072S controller, read chapter 8 "System variables" of the user manual "Installation and operation in the RFC 4072S Remote Field Controller with integrated safety-related PROFINET controller (part. no. 108580_en_01). |

Monitoring the Profisafe Device Status

With regard to the monitoring of the operational state of Profisafe F-Devices, the following status types are distinguished and different diagnostic system variables are relevant:

| Status type | Relevant diagnostic system variable |

|---|---|

| Device passivated | F-Device has been passivated. The system variable is available F-Device-related (F_ADDR_XXXXX_PASS_OUT) and globally (PASS_OUT_GLOBAL).Possible reasons for the device passivation:

|

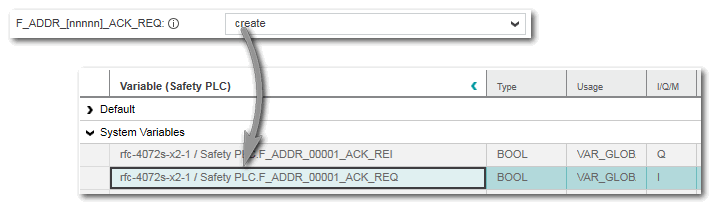

| Device waits for operator acknowledge | F-Device requires an operator acknowledge request after

removing a communication, or CRC, watchdog or F-Device error. The system variable is available F-Device-related (F_ADDR_XXXXX_ACK_REQ) and globally (ACK_REQ_GLOBAL).Acknowledgment can be done after removing the error cause by setting the device-related management system variable F_ADDR_XXXXX_ACK_REI or the global management variable ACK_REI_GLOBAL to TRUE. Observe the hazard message below this table. |

| Device fault | Error in an F-Device. The system variable is available F-Device-related (F_ADDR_XXXXX_DEVICE_FAULT) and globally (DEVICE_FAULT_GLOBAL).After such a device error has been reported, proceed as follows:

|

| Channel fault and Acknowledgment | Channel fault of an F-Device waits for Acknowledgment by the operator. The system variable is available F-Device-related (F_ADDR_XXXXX_CHF_ACK_REQ) and globally (CHF_ACK_REQ_GLOBAL).After such a channel error has been reported, proceed as follows:

|

| I-Parameters applied | The F-Device with the F-address XXXXX indicates that the I-Parameters have been applied: F_ADDR_XXXXX_IPAR_OK

Applying the I-Parameters of an F-Device is initiated by setting the device management system variable F_ADDR_XXXXX_IPAR_EN to TRUE. For detailed information on the device-specific process of applying I-Parameters, please refer to the

user manual of the respective device. Observe the hazard message below this table. |

|

WARNING

|

Unintended start-up

|

| Further Info

For a detailed description of all available Profisafe system variables, refer to the respective controller user manual. For the RFC 4072S controller, read chapter 8 "System variables" of the user manual "Installation and operation in the RFC 4072S Remote Field Controller with integrated safety-related PROFINET controller (part. no. 108580_en_01). |

Enabling the creation of diagnostic Profisafe system variables

For each diagnostic Profisafe system variable the Safety PLC involved provides, you can determine whether the variable is to be created in PLCnext Engineer or not. This way, the number of available system variables in the Safety PLC Data List can be limited according to your requirements.

By default, the most important and commonly used variables are set to 'create'.

- In the PLANT, double-click the 'Safety PLC' node and open the 'Settings' editor.

- In the Profisafe categories set those variables to 'create' which you want to use for monitoring and evaluation purposes in your application.