Configuring the IO-Link System for Profinet

There are several steps for configuring the IO-Link system for Profinet. First, the IO-Link master has to be added to the PLCnext Engineer project and configured. In the second step, the IO-Link ports of the IO-Link master have to be configured by assigning devices to the ports.

This topic provides information on the following:

Adding and configuring the IO-Link master

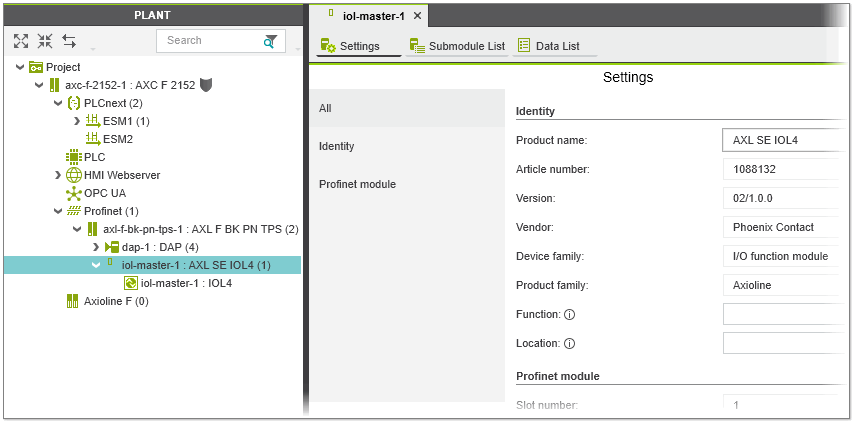

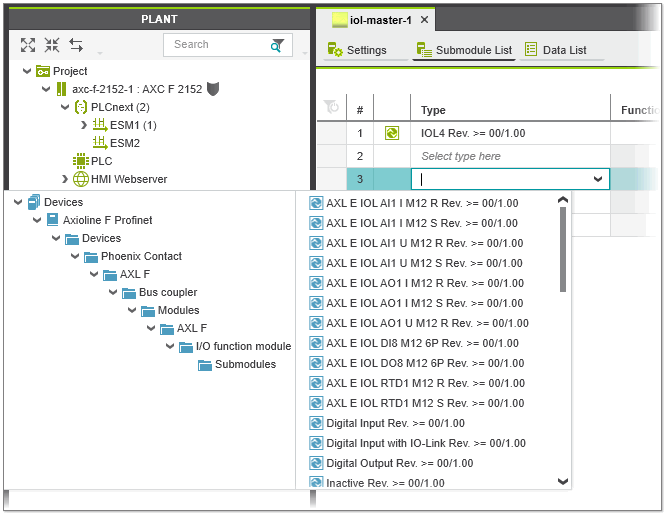

- Add the IO-Link master in the PLANT under the Profinet bus coupler node either via the Station Editor, by drag and drop from the COMPONENTS area or by scanning your network.Example:

- Double-click the IO-Link master node in the PLANT and adjust the necessary settings in the 'Settings' editor.

Assigning devices to IO-Link ports

The ports of the IO-Link master can be operated in different operation modes. For each IO-Link port, the operation mode is configured by assigning a device (IO-Link device, DI or DO module) via the master's 'Submodule List' editor.

In addition to the standard IO-Link devices provided with the installation, you can connect and configure IO-Link devices from any manufacturer. Using the 'File > Import > Import IODD File(s)' function, IODD files (IO-Link V1.1) from other manufactures can be imported into your project and subsequently assigned to ports of the IO-Link master (see the topic "Importing IODD Files" for details).

Proceed as follows:

- If the IODD files of the devices to be assigned to the IO-Link ports are not available in your project, import the files via 'File > Import > Import IODD File(s)'.

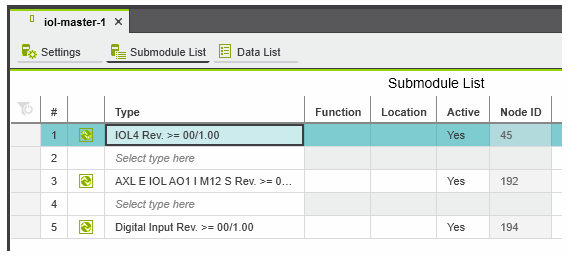

- In the PLANT, double-click the IO-Link master under the Profinet bus coupler node and select the 'Submodule List' editor. The 'Submodule List' editor shows the list of the ports of the IO-Link master where each table row represents one IO-Link port.

- For each port, select a suitable device (IO-Link device, DI or DO module) which you want to operate on the port. To do this, click in the respective 'Type' table cell and select the device from the appearing list (see the following example). The list provides all IO-Link devices for selection that are allowed to connect (coming with the PLCnext Engineer installation and imported via IODD files).Alternatively, drag the device from the COMPONENTS area onto the desired table row. (In the COMPONENTS area, the imported IO-Link devices are available under the 'Local' folder in the 'Network' category.)

In doing so, the following applies:

In doing so, the following applies:- The operation mode of the port and the device data such as the Device Id, Vendor ID, etc. are automatically entered in the 'Parameters' editor of the IO-Link device.

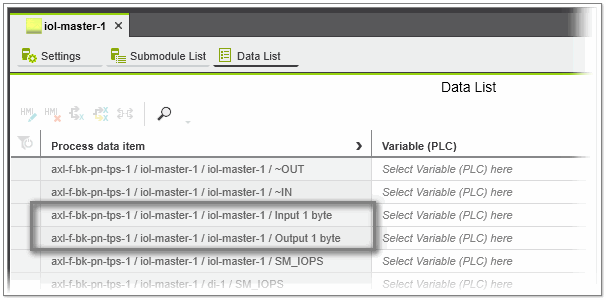

- The individual process data of the device appear in the 'Data List' of the master (the data are also available in the 'Data List' of the IO-Link device).

- In the PLANT, the IO-Link device appears as submodule of the IO-Link master with the corresponding port number preceding the device name. Double-clicking the node in the PLANT opens the corresponding editors in the editors area. Here you can parameterize the device and link the process data to the project variables.

Note

Ensure that the port configuration in PLCnext Engineer corresponds to the actual configuration on the IO-Link master. - Once you have assigned the IO-Link devices, parameterize them in the 'Settings' and 'Parameters' editors of the device (the parameters to be set are derived from the IODD file provided by the manufacturer of the device and may differ for each device). To open the device editors, double-click the IO-Link device in the PLANT and activate the corresponding editor in the editors group. In the 'Data List' editor of the device, link the process data to your project variables (observe the following note).

For information how to include the startup parameters for the IO-Link device in the Profinet configuration, see the description below.

Writing startup parameters for the IO-Link device

In the IODD file of an IO-Link device, some parameters are defined as startup parameters. The startup parameters are used to configure the behavior of the IO-Link device at startup. These parameters are stored retentively in the flash memory of the device. During startup, the IO-Link master automatically starts up the IO-Link devices and transfers the Profinet configuration to the IO-Link devices. The Profinet configuration contains the submodules, devices etc. you have configured in your project and also the device-specific startup parameters.

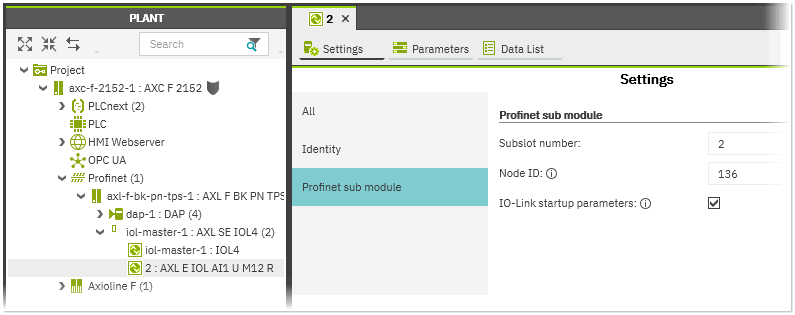

By default, the device-specific startup parameters for the IO-Link device are included in the Profinet configuration. You can disable the automatic insertion of the startup parameters into the Profinet configuration and thus exclude the parameters from writing to the IO-Link device by deactivating the 'IO-Link startup parameters' checkbox for the desired IO-Link device. The checkbox is available in the device's 'Settings' editor under the 'Profinet sub module' category.

Removing IO-Link devices

To remove an IO-Link device from the master configuration, select the 'Delete' command from the IO-Link device node in the PLANT or select the node and press <Del>. Alternatively, select the device in the master's 'Submodule List' and press <Del> or select 'Delete' from the device's context menu.