Functional description

Dieses Thema enthält die folgenden Abschnitte:

- Muting operation (without override function)

- Muting errors

- Override function

- Example of a muting operation (without override function)

- Example of a muting operation (with override function)

- Start-up inhibit (S_StartReset)

To this end, it evaluates the following signals:

- the signals of two muting sensors,

- the status signal of the safety-related equipment (light grid),

- the feedback signal from the muting lamp,

- an enable signal for the muting operation,

- a request signal for the override function.

A start-up inhibit can be specified at S_StartReset.

The function block switches the enable signal at the S_AOPD_Out output in accordance with the input signals present. It executes stop category 0 at this output.

| Hinweis

The signal at the S_AOPD_Out output is the enable signal for the entire process. In order to process the enable or, equally, the request for the defined safe state in the functional safety system, the signal must be used in the safety logic in such a way that a SAFEFALSE signal at the S_AOPD_Out output stops the zone of operation from being used. |

Muting operation (without override function)

The overall muting operation is divided into different muting sequences.- Protecting the zone of operation.

The safety-related equipment is active when muting is not active: If the function block does not detect an active muting operation at the muting inputs, a SAFEFALSE signal from the light grid ("object detected") leads to the defined safe state SAFEFALSE at the S_AOPD_Out output (e.g., "stop machine"). - Activating the muting operation.

The safety-related equipment is deactivated: If the state of the muting sensors changes from SAFEFALSE to SAFETRUE within the discrepancy time set at DiscTimeEntry (because both sensors detect an object which is permissible for the muting operation, for example), the muting operation is activated and the safety-related equipment deactivated. - Muting operation is active.

The safety-related equipment is deactivated for as long as the muting operation is active (because both sensors detect an object which is permissible for the muting operation, for example). A SAFEFALSE signal from the light grid ("object detected") does in this case not cause the S_AOPD_Out output to switch to the defined safe state SAFEFALSE (e.g., "stop machine"). The muting operation must be completed within the maximum muting time set at MaxMutingTime. If it is not, the S_AOPD_Out output switches to the defined safe state SAFEFALSE (e.g., "stop machine"). - Completing the muting operation.

The safety-related equipment is active again. The muting operation is complete as soon as a muting sensor switches from SAFETRUE to SAFEFALSE (i.e., no object is detected any longer within the detection area). The safety-related equipment is reactivated at the same time when the S_MutingActive output switches to SAFEFALSE.

Muting errors

Errors which occur during the muting operation are called muting errors. As a result, muting is interrupted and the safety-related equipment gets activated. The safety-related equipment can then be temporarily deactivated by means of the override function (see below).

Muting errors are:- The discrepancy time DiscTimeEntry has elapsed.

- The maximum muting time MaxMutingTime has elapsed.

- Invalid muting sequence (by appropriate signals at inputs S_MutingSwitch11, S_MutingSwitch12, and MutingEnable).

If override is not requested in the event of a muting error, the outputs behave in the following way:

- The S_AOPD_Out output switches to the defined safe state SAFEFALSE (e.g., "stop machine"),

- The Error output switches to TRUE.

Override function

If the muting is interrupted by an error (e.g., the maximum muting time MaxMutingTime has elapsed because of an impermissible object), the safety-related equipment gets activated. This can be temporarily deactivated by the override function, e.g., to clear the zone of operation from the impermissible object.

The override function can only be used in the event of a previous muting error. The sequence is then as follows:- Normal sequence of the muting operation as described in the steps 1-3 above.

- Protecting the zone of operation by activating the safety-related equipment.

- Activating the muting operation and deactivating the safety-related equipment by the muting.

- A muting error occurs (see description above).

The muting gets interrupted, e.g., by an impermissible object. The Error output switches to TRUE and the S_AOPD_Out output switches to the defined safe state SAFEFALSE (e.g., "stop machine"). Now, an override operation is possible (output OverridePossible = TRUE). - Override is started by the operator.

An override operation can be started by a SAFETRUE signal at the S_StartStopOverride input, if the OverridePossible output = TRUE. This initiates the override timer (MaxOverrideTime input). The start is caused by activating the connected control device and must be maintained for the overall override duration (e.g., by a key switch).

The safety-related equipment is deactivated for as long as the override operation is active. A SAFEFALSE signal from the light grid ("object detected") does not then cause the S_AOPD_Out output to switch to the defined safe state SAFEFALSE (e.g., "stop machine"). Now, the impermissbile object can be removed from the zone of operation. - Interrupting or exiting the override operation.

The override operation gets interrupted as soon as the operator releases the control device (e.g., a key switch) (S_StartStopOverride input = SAFEFALSE). The output OverrideActive becomes FALSE and S_AOPD_Out switches to the defined safe state SAFEFALSE (e.g., "stop machine"), and the override timer MaxOverrideTime continues to run. The override operation can be restarted as long as MaxOverrideTime has not elapsed. Override gets automatically exited when all muting sensors and the light grid detect no more object or when the override timer MaxOverrideTime has elapsed.

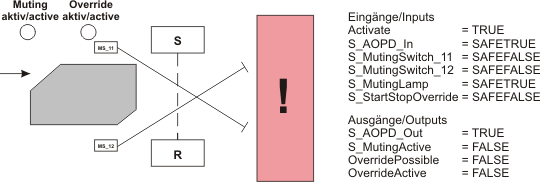

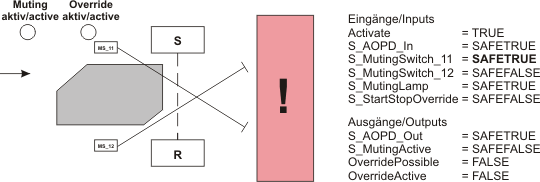

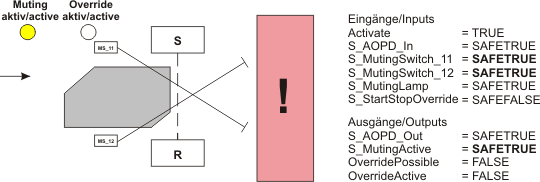

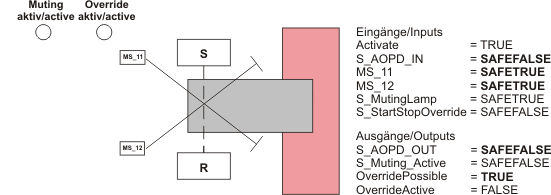

Example of a muting operation (without override function)

The graphic below shows an example of a muting operation.

| Hinweis

The sensor beams can also be interrupted in a different sequence. |

| Hinweis

In the graphic, only the values of the inputs and outputs which are relevant for this illustration are given. |

- MS_11: Muting sensor 1 (top), connected to the S_MutingSwitch11 function block input.

- MS_12: Muting sensor 2 (bottom), connected to the S_MutingSwitch12 function block input.

- Signaling unit (e.g., lamp) "muting active", controlled via function block output S_MutingActive.

- S/R: safety-related equipment (e.g., light grid), consisting of a transmitter (S) and a receiver (R), connected to function block input S_AOPD_In. The function of this safety-related equipment is deactivated/activated by means of the muting operation.

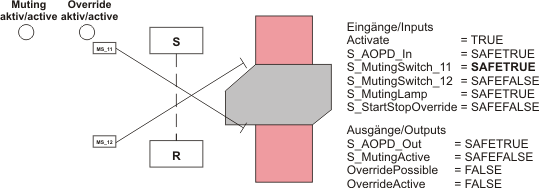

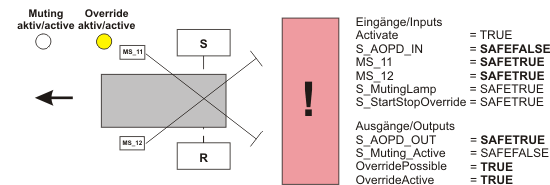

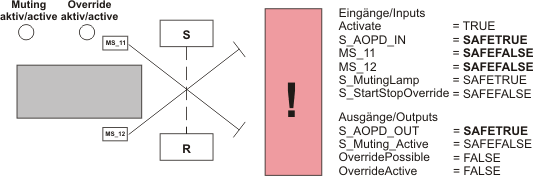

Example of a muting operation (with override function)

In the event of an error during the activated muting in the muting operation described in the example above, the last step does not occur (muting inactive again). All requirements for an override operation are then fulfilled and the further sequence is shown below.

|

|

|

|

|

|

| Hinweis

As the override operation in this example has been completed within the time specified at the MaxOverrideTime input, the S_AOPD_Out output remains SAFETRUE and no error is detected (Error remains FALSE). Exceeding would result in an error (Error output = TRUE) and the S_AOPD_Out output would be switched to the defined safe state SAFEFALSE (e.g., "switch off machine"). |

Start-up inhibit (S_StartReset)

S_StartReset is used to specify the start-up inhibit after activating the function block and/or starting the Sicherheitssteuerung.

| S_StartReset = SAFEFALSE | After the Sicherheitssteuerung has been started up and/or the function block has been activated at input Activate, the start-up inhibit is active. The start-up inhibit is only removed if there is a positive signal edge at the Reset input.Refer to the first warning below this table. |

| S_StartReset = SAFETRUE | After the Sicherheitssteuerung has been started up and/or the function block has been activated at input Activate, no start-up inhibit is active.Refer to the second warning below this table. |

Removing the start-up inhibit by means of a positive signal edge at the Reset input can cause the S_AOPD_Out output to switch to SAFETRUE immediately (depending on the status of the other inputs).

|

WARNUNG

|

Unintended start-up

|

|

WARNUNG

|

Non-conformance to safety function requirements

|