Controller Commissioning: From Compiling to Debugging

|

WARNING

|

Unintended machine operation

|

| Note

Both the Safety PLC and the standard (non-safety-related) controller have their own, separate Cockpit and both can be connected and commissioned independently of each other. Therefore, both PLANT nodes provide separate context menu commands to write and start the standard project and the safety application independently. It is, for example, possible to write and start the standard application while simulating the safety-related application. See help chapter "Controlling the Safety Application from the Safety Cockpit". Safety download combined with standard download: However, it is possible to write and start the safety application together with the standard application. For that purpose, the commands 'Write and Start Project (incl. Safety)' (with and without project sources) are available. The following procedure also takes this case into account. |

- Verify the following:

- Controller and all configured devices are available in the network.

- Application structure modeled in the PLANT represents the physical network.

- IP address settings in the 'Settings' editor of each device involved are correct (controller node and PROFINET device nodes). If required, adjust the IP settings as described in the topic "Device Configuration/Parameterization".

- No errors are pending in the Error List (MESSAGES window).

- Programming mode is active and

debug mode is inactive, i.e., the controller node icon does not indicate a controller status and the controller name is not shown bold in the PLANT. Reason: the project cannot be written to the controller while online and debug data is exchanged in debug mode.

If on, switch the debug mode off by selecting 'Debug On/Off' from the context menu of the controller in the PLANT or in the ONLINE STATE window, or deactivate the corresponding icon on the 'Cockpit' toolbar:

Note

Poor internet connection? Performance problems due to VPN connection? You can adapt the TCP communication settings by increasing the handshake timeout value and the polling interval. See topic "TCP Communication Connection". - Set the controller (not the controller simulation) as target system.

- Double-click the controller node in the PLANT to open its properties in the editors area.

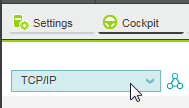

- In the editors area, open the 'Cockpit' editor.

- In the 'Cockpit' editor, select 'TCP/IP' from the drop-down list.

If the controller provides several ports, set the port to which the LAN cable is connected.

Otherwise, the online commands you execute during commissioning will be applied to the controller simulation (if available for the controller type involved).Note

If you have configured a redundant control system built up with, for example, two RFC 4072R controllers, the drop-down list provides all TCP/IP LAN ports of the controllers for selection. This allows you to access both controllers in the redundant system in order to gather, for example, status information for the purpose of diagnostics of the redundant control system.

For detailed information, see the topic "Configuring a Redundant Control System".

Note

Ad-hoc IP address instead of project-defined address

Instead of the IP address defined in the controller settings of the project, you can also connect to a controller with any other IP address (provided it can be accessed in the network). In this way, communication connections to several PLCnext devices can be established one after the other (e.g. in router scenarios) without having to change the IP address in the project settings and rebuild the project. How to do this is described under "Ad-hoc IP address instead of project-defined address". - Create the project image (build the project), send it to the controller, and start the program execution.

The project image contains the application logic as machine-readable code and all relevant configuration/parameterization data of the project. If an HMI application has been developed in the project, the HMI data are also sent to the controller.Note

When writing the project to the controller and starting up the application, observe the safety warning message noted at the beginning of this topic.

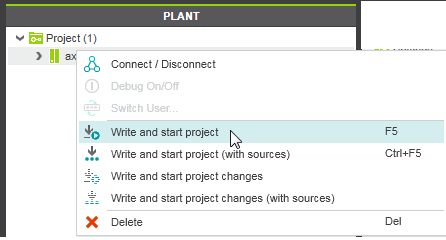

Building the project, sending, and starting the project execution is possible with only one command:In the PLANT, right-click the controller node and select the desired 'Write and start project' from the context menu or press <F5> on your keyboard. It is possible to combine the safety download with standard download. (See also the help section "Further 'Write and Start' commands..." below.) Alternatively, select the command in the context menu of the controller in the ONLINE STATE window, or click the following icon on the 'Cockpit' toolbar:Note

Code worksheets of a POU can be excluded from compilation. Worksheets with this flag set will be ignored by the compiler during the build process. See the topic "Excluding Code Worksheets from Build" for details. Refer to the topic "Controlling the application / Toolbar icons in the Cockpit" for detailed information on the 'Write and Start' command.

Refer to the topic "Controlling the application / Toolbar icons in the Cockpit" for detailed information on the 'Write and Start' command.

'Write and Start' aborted due to compiler errors?

'Write and Start' aborted due to compiler errors?

Further 'Write and Start' commands...

Further 'Write and Start' commands...

On the controller, the project is automatically stored as Boot Project in the Flash Memory. As a result, the controller will automatically execute this project after each start-up.PLCnext Engineer automatically attaches to the process and switches to Debug mode when the project execution has been started after a 'Write and Start' command. Not yet logged on to the controller?

Not yet logged on to the controller?

- Perform a function test after the successful controller startup. To support you in this, PLCnext Engineer provides the following features:

- Debug mode in which online values are read cyclically from the controller and displayed in the editors.

- Debug commands, such as forcing/overwriting of variables and breakpoints.

After activating an extended debug option in the Cockpit, debugging of functions, methods, inline transitions and actions is possible. This option, however, increases the execution time and memory consumption on the controller. - For SFC worksheets, additional SFC-specific debug commands are available.

- WATCHES window for collecting variables from different worksheets, displaying their online values and execute debug commands.

- LOGIC ANALYZER for recording and graphical representation (as curves) of variables values read from the running controller.

If you detect incorrect behavior or an error in the application logic during the function test, you must make certain that it will not lead to a hazardous situation. Observe the safety warning message noted at the beginning of this topic. Next, remove the error in the application logic by reediting the project. Following a successful compilation, start commissioning again.Safety download combined with standard download:Note

The test of the application in debug mode using debug commands, the WATCHES window and LOGIC ANALYZER may not replace the proper function test using I/O devices/sensors/actuators under any circumstances. The test in debug mode may only be performed in addition to the standard function test, as a preliminary test, for example.

If you have included the safety project image by selecting one of the commands 'Write and Start Project (incl. Safety)' (with and without project sources), you must additionally perform a safety-related function test. With a few exceptions, the same debug and monitoring tools are available for the safety application as for the standard application. Refer to the corresponding help topic in the chapter "Safety PLC Commissioning: From Compiling to Debugging".

| Note

After the modification of safety-related parameters: If you have changed safety-related parameters (such as F-parameters or channel-related parameters), you have to write additionally the safety-related project to the Safety PLC. If only the standard controller is updated, Profinet cannot become operational. Refer to the topic "Safety Parameters Editor", section "After a safety parameter modification  ‣ 'Safety Parameters' Editor - only for Safety-related Devices and Modules ‣ 'Safety Parameters' Editor - only for Safety-related Devices and Modules

×‣ 'Safety Parameters' Editor ×" for details. In such a case, use the command 'Write and Start Project (incl. Safety)' (with and without project sources) to combine the standard application and the safety application. |

Controller simulation: optional addition to the function test

PLCnext Engineer additionally provides a function for simulating the application, which you can use to test the behavior of the application logic (including HMI and code from PLCnext Engineer libraries) fully independently of the real hardware. Simulation mode offers an option to force variables and set breakpoints, too.